Product Details

PRODUCT CENTER

Anti blocking screen

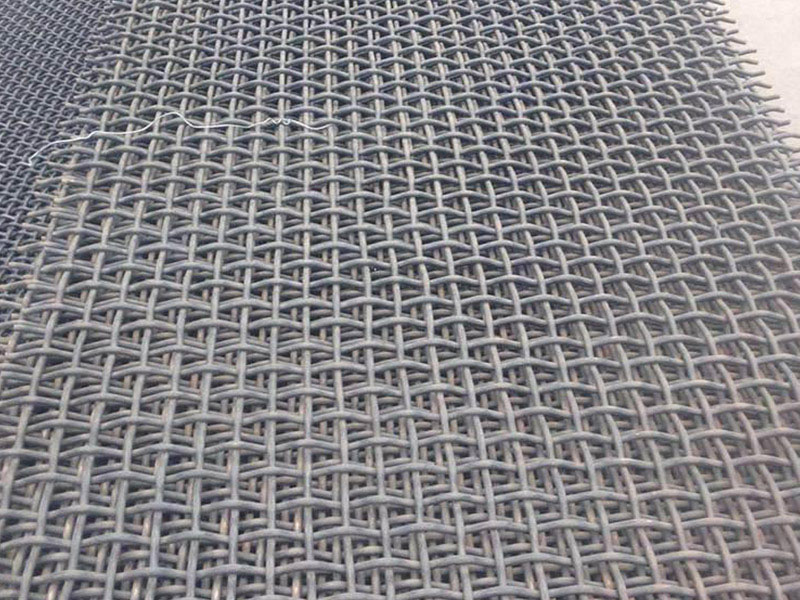

1. Rectangular mesh screen

On the premise of meeting the screening process requirements, the rectangular mesh is deformed and a certain proportion of rectangular holes are used. For example, the original 3.5x3.5mm mesh is changed into 3.5x5mm or longer rectangular holes (as shown in Figure 1). But the direction of the mesh is different, which will affect the screening accuracy and the service life of the screen to a certain extent.

The flake material in the stone is easy to be screened out when the screen is screened. Therefore, this kind of screen can only be used for screening materials with no serious plugging and no flake in stone.

Rhombic anti blocking screen

2. Rhombic hole anti blocking screen, which is woven by two identical screen strips with tiny vibration. It has a good effect of anti plugging.

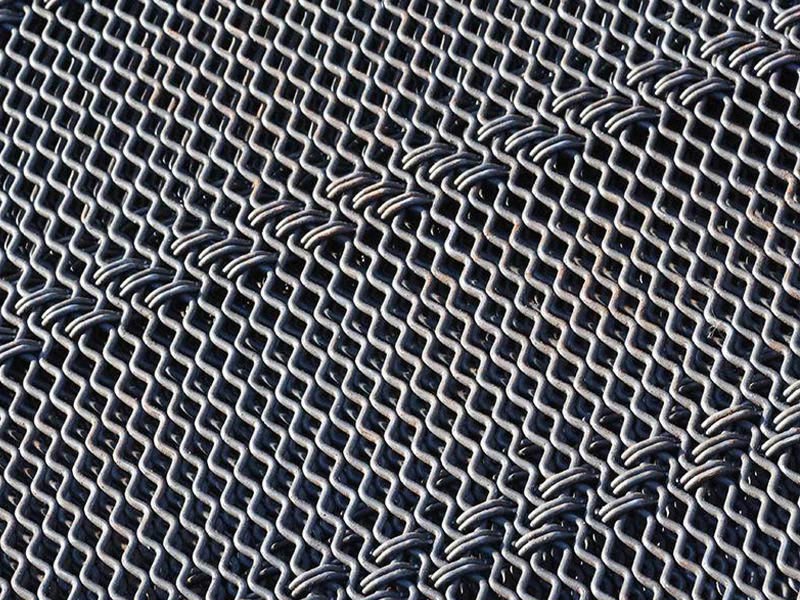

Triangle anti blocking screen

3. Triangle hole anti blocking screen. The screen is characterized by two adjacent screen strips, one is static screen strip and the other is moving screen strip.

Its basic principle is to extend the two-dimensional fixed hole in the plane to the three-dimensional variable mesh, and to establish effective vibration difference by using the secondary vibration generated by the random vibration of adjacent screen strips. It realizes the continuous change of screen hole in screening, so there is no fixed critical particle stone. The specific method is to set a moving screen bar with relatively large vibration amplitude in two relatively stationary static screen bars, and the moving screen bar can bounce up the stone during jam or make it pass the screen. According to the characteristics of the stone, the relative elastic strength and vibration amplitude of the static and dynamic screen strips are adjusted accordingly, which can make the screen in a good screening state. The screening efficiency can be increased by about 30% compared with the fixed mesh screen. The self-cleaning function of the screen is basically realized, and the blockage of the screen hole is greatly reduced.

The static screen bar of the screen is thicker than the moving screen bar, so it not only increases the wear resistance of the screen, but also improves the screening efficiency. At the same time, the screen bar structure of the screen can greatly reduce the contact point between the stone and the screen hole, and reduce the occurrence of hole plugging.