Product Details

PRODUCT CENTER

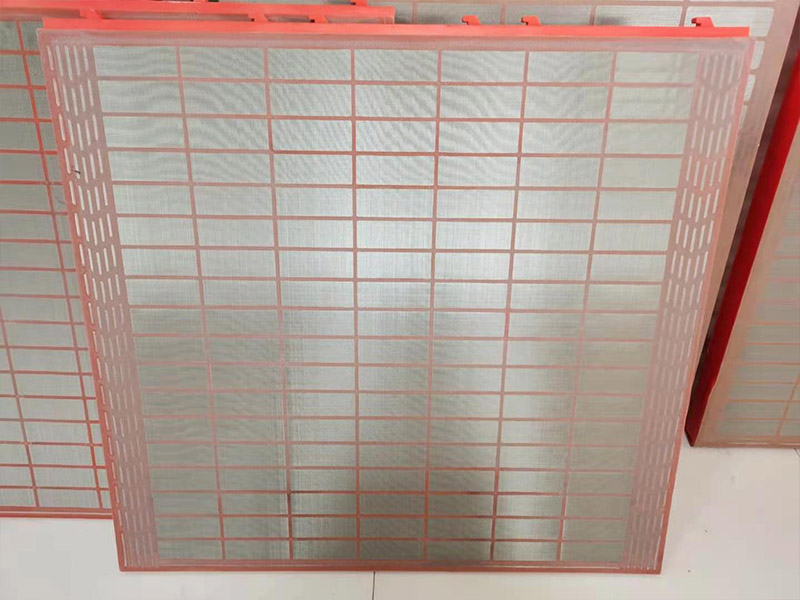

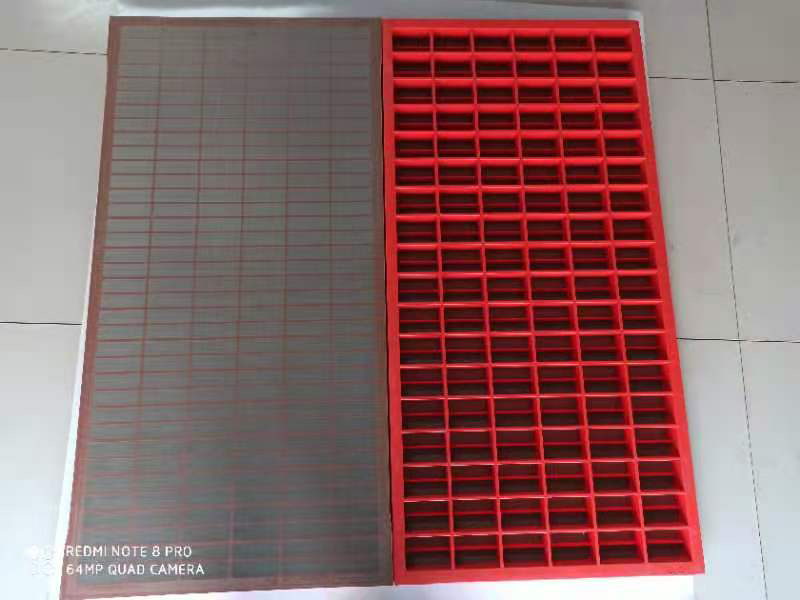

Polyurethane frame screen

Polyurethane screen plate belongs to mine equipment, which is used in mining and quarrying plants combined with vibrating screen and other mining equipment.

Chemical composition: Polyurethane

Chinese Name: Polyurethane

The structure of polyurethane: Polyurethane

Classification: Polyurethane dehydrated screen and polyurethane strip slit screen plate

Source: polymer compound formed by the interaction of binary or polyisocyanate with binary or polyhydroxy compounds.

According to the structure of polyurethane screen plate, there are four types:

1) Mosaic

2) Bolted connection

3) Strip connection

4) Screen hook connection

Polyurethane wire mesh (wrapped with metal wire and core wire welding net support net) has beautiful appearance, bright color, light weight, high mechanical strength, heat insulation, sound insulation, corrosion resistance and excellent weather resistance, without secondary decoration and various colors.

1. The tensile strength, tear resistance, wear resistance, rebound, compression deformation are small, and the service life is long.

2. Strong binding force with metal matrix, not easy to start and remove

3. High surface finish and stable size. High strength composite screen, belonging to the technical field of screening equipment, is used to solve the problems of low strength and short service life of ordinary wire mesh. The utility model is composed of a web and a supporting net, which is improved in that the net is a metal mesh and a support net is a polyurethane support net. The polyurethane support net is located under the metal mesh, and it is a grid with a vertical and horizontal intersection, and the longitude and weft strips are composed of steel wire rope core and polyurethane surface. The above-mentioned improvement gives the utility model a good performance different from the common metal screen. It has high strength, rigidity and bearing capacity, and can effectively reduce vibration noise and improve the service life of screen. The utility model can be made into various shape screening devices, especially for high frequency vibrating screen with electromagnetic excitation. It can be widely used in screening, filtration, dehydration, desilting and other operations in many industries.

8mmx5mm hole 1.2m X5 M

8mmx12mm hole 1.5m X5 M

8mmx20mm hole 2m X5 M

It is suitable for vibration screen of metallurgy, coal, chemical industry, construction and other departments. It is used as fine-grained screening in bulk materials, dry and astringent. It can also be used for classification of some corrosive materials.