Product Details

PRODUCT CENTER

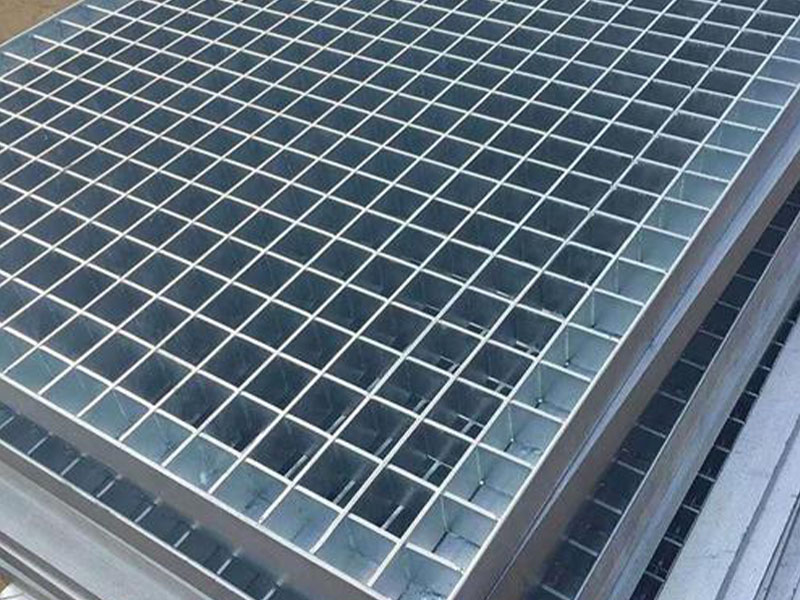

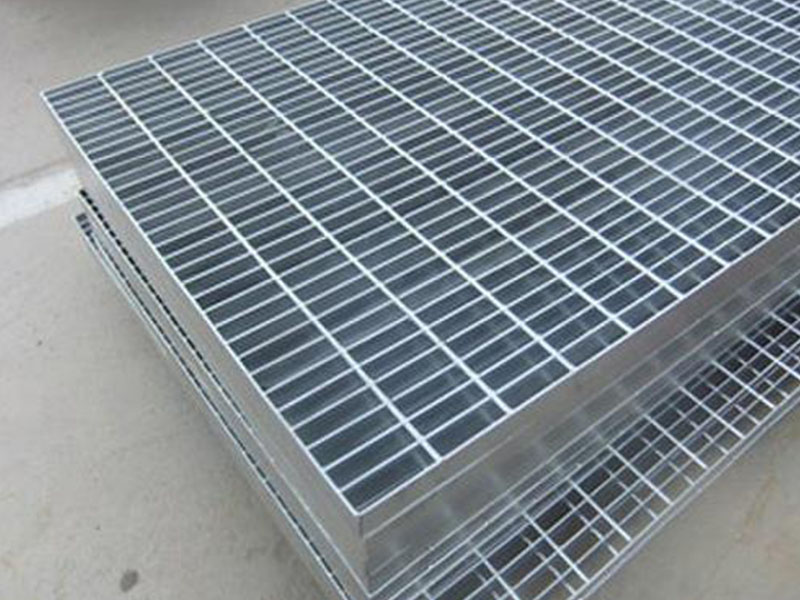

Steel grating

The steel grating is a kind of steel product which is cross arranged with flat steel and cross bars (twisted square steel, square steel, round steel, flat steel, etc.) according to a certain spacing, and welded into a square lattice in the middle. The steel grating is mainly used for making ditch cover plate, steel structure platform plate, steel ladder step plate, etc. the cross bar is generally made of twisted square steel. The steel grating is generally made of carbon steel, Hot dip galvanizing on the surface can prevent oxidation. It can also be made of stainless steel. The steel grating has the properties of ventilation, lighting, heat dissipation, anti-skid, explosion-proof and so on.

The production standard of steel grating: * * yb4001-1991, Yb / t4001-1998. It can also be produced according to British bs4592-1-1995 and American ANSI / NAAMM (mbg531-88).

Manufacturing method of steel grid plate: pressure welding steel grid plate is a kind of product required by customers, which is made of load flat steel and cross bar arranged by a certain spacing, longitude and latitude, welded into original plate by 200 tons of hydraulic resistance welding automation equipment, and processed by cutting, opening, wrapping and other processes.

Load flat steel spacing: the center distance between two adjacent load flat steel, commonly used 30mm, 40mm two kinds.

Cross bar spacing: the center spacing of two adjacent cross bars is usually 50 mm, 100, two kinds, which can be produced according to customer requirements. Compared with checkered plate and other grilles,

The steel grating has the following advantages:

Material saving: under the same load condition, the material saving method can reduce the material of supporting structure.

Reduce investment: save materials, labor, construction period, no cleaning and maintenance.

Simple construction: the pre installed support is fixed by bolt clamp or welding, which can be completed by one person.

Save time: the product does not need to be reprocessed on site, and the installation is very fast.

Durable: after hot-dip galvanizing anti-corrosion treatment before leaving the factory, it has strong resistance to impact and heavy pressure.

Modern style: beautiful appearance, standard design, ventilation and light transmission, giving people a modern feeling of overall fluency.

Light structure: less materials, light structure, and easy lifting.

Reduce wind resistance: due to good ventilation, wind resistance is small in case of strong wind, reducing wind damage.

Anti Dirt: no rain, ice, snow and dust.

Ventilation, lighting, heat dissipation, explosion-proof, good anti-skid performance

Simple design: no need for small beam, simple structure and simple design; There is no need to design the detailed drawing of steel grating, only the model can be indicated, and the manufacturer can design the layout for customers.

Acid and alkali corrosion ability: in the range of pH 6 to pH 12.5, a stable protective film is formed on the surface of zinc layer, with good corrosion resistance.