Product Details

PRODUCT CENTER

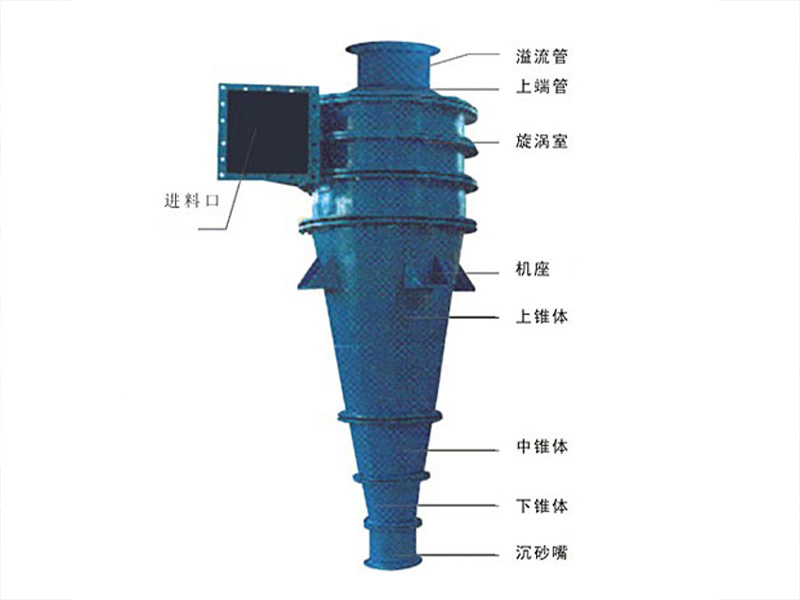

Hydrocyclone

Development history

Hydrocyclone * appeared in the Netherlands as early as the late 1930s. Hydrocyclones are classified by rotating flow, and also used for concentration, dehydration and separation. Its structure is simple, mainly composed of a hollow cylinder L and cone 2. The diameter of the cylinder represents the specification of the hydrocyclone. The size of the pipe varies greatly, from 50mm to 1000mm, usually 125-500mm. An overflow pipe 5 is inserted in the center of the cylinder, and a feeding pipe 3 is connected along the tangent direction, and a sand settling port 4 is reserved at the lower part of the cone. Under the pressure, the slurry is fed into the hydrocyclone along the feeding pipe, and then it is rotated under the restriction of cylinder wall. Coarse particles are thrown to the wall due to the large centrifugal force of inertia, and gradually flow down from the bottom to become sand. The velocity of fine particles moving towards the wall is small, and the liquid flowing toward the center drives the flow from the center overflow pipe to become overflow.

characteristic

Hydrocyclone is a kind of high efficiency classification and desilting equipment. Because of its simple structure, easy manufacture and large processing capacity, it has been widely used at home and abroad. Its main disadvantage is that it consumes more power and wear seriously in high pressure feeding. New wear-resistant materials such as hard alloy and silicon carbide are used to make wear-resistant parts of grit opening and ore feeding port, In addition, when used in the classification of closed-circuit grinding, because of its small volume, it has no buffer capacity for ore fluctuation, so it is not as stable as mechanical classifier.

brief introduction

Hydrocyclone is used to separate and remove heavy coarse particles of mud and sand in sewage. Sometimes it is also used for mud dewatering. It is divided into two types: pressure type and gravity type, and it is usually made of circular column structure or metal pipe. The water enters by pressure or gravity from the upper part of the structure (or metal pipe) along the tangent line. Under centrifugal force, the coarse and heavy particles are thrown to the wall of the device and rotated down to discharge together with the formed concentrated liquid. The smaller particles are discharged with the secondary uprotation eddy current after rotating to a certain extent.

Construction principle

The hydrocyclone consists of a hollow cylinder at the upper part, an inverted body connected with the cylinder at the lower part, and the two two are the working cylinder of the hydrocyclone. In addition, the hydrocyclone has feed pipe, overflow pipe, overflow pipe and grit chamber.

The hydrocyclone uses sand pump (or height difference) to screw the pulp into the cylinder along the tangent direction at a certain pressure (generally 0.5-2.5kg / cm) and flow rate (about 5-12 M / s), and then the slurry will rotate along the wall of the cylinder at a very fast speed to produce centrifugal force. The coarse and heavy ore particles are thrown out by centrifugal force and gravity.

Hydrocyclone is mainly used in the separation, separation, concentration and desilting in the beneficiation industry. When hydrocyclone is used as classification equipment, it is mainly used to form grinding classification system with mill; It can be used for desilting in the re - dressing plant when used as sludge removal equipment; When used as the equipment of concentration and dehydration, it can be used to concentrate the tailings of mineral processing and then send it to fill the underground mining tunnel.

Hydrocyclone has no moving parts and simple structure; The production capacity of unit volume is large and the area is small; The classification efficiency is high (up to 80% ~ 90%), and the grading granularity is fine; Low cost and low material consumption.

The suspension enters the hydrocyclone along the tangent direction at a higher speed. Due to the limitation of the outer cylinder wall, the liquid is forced to rotate from top to bottom, which is usually called the outer or descending swirl. The solid particles in the outer swirl are subjected to centrifugal force. If the density is greater than the density of the surrounding liquid (this is most cases), the greater the centrifugal force it is subjected to. Once the force is greater than the liquid resistance caused by the movement, the solid particles will overcome this resistance and move towards the wall of the device, and separate from the suspension, and the particles near the wall will be driven by continuous liquid, The flow is moved down the wall of the device, and then it reaches the bottom flow port and gathers into a highly thickened suspension, and then it is discharged from the bottom flow port. After the separation and purification of the liquid (of course, some small particles) rotate downward and continue to move down. After entering the cone section, the rotating speed of the liquid is accelerated due to the gradual reduction of the inner diameter of the rotating liquid separator. Because the pressure distribution along the radial direction is uneven when the liquid produces eddy current movement, the smaller the pressure is near the axis and near zero when it reaches the axis, and becomes the low pressure area or even the vacuum area, which leads to the liquid moving in the axial direction. At the same time, because the bottom flow port of the rotary liquid separator is greatly reduced, the liquid can not be discharged from the bottom flow port rapidly. The overflow port in the center of the top cover of the swirl chamber moves a part of the liquid to it due to its low pressure zone, thus forming upward rotation movement and discharging from the overflow port.